Llunia i fyny yn y sefyllfa cynnigol gyda'r mold lwsio Aluminium OEM gan Moldie, cynorthwywr lleoli diesau lwsio sy'n cynnig safonau cyfanlofrifol a chustomodiad ddim ond un.

Wedi ei gyfrifoli gan ddefnyddio sylweddau mwl ar ran uwch fel LKM, HASCO a DME, mae ein chynghorion llusgo yn cael eu cyfeirioli i ddatrys.

Mae'r materiâu mwl sy'n mynd o 45# i 1.2738 yn cynnig amrywiad anhygoel o ddiogres. A drwy gymryd cam o PC/ABS i POM, maen nhw'n gweithredu i angen llawer o wahanoldeb.

Does dim ond hynny; mae gwahaniaethu trawiadau preswyl, opsiynau rhan goch neu gynnes, a chydnabyddiaeth gyda meicroffewn llusgo rhwng 80-1500Ton yn dangos yr addasrwydd yma o blentynau.

Mae pob lân wedi'i greiddio artiffedigol, yn cyflawni safonau MT, YS ac HN, a phanellir yn elgan yn unigol i'w fathiant RAL PANTONE.

Yn ogystal, maen nhw wedi eu tystio yn ôl ISO 9001:2015. Ar droi gyfan, cysylltwch â ni heddiw a chyfeirwch atoch chi.

| BRAND | Moldie |

| Sylfaen Mold | LKM C50 + P20 ar gyfer AB, Plwm ffrwdol ac ati. |

| Mewnmychiadau (camgymeriad a chore) | Dievar, H13, 8407, 1.2344 neu'r materiol rydych yn ei ofyn am. |

| Safon | HASCO, DME, MISUMI, PUNCH ac ati. |

| Deunydd cynnyrch | ADC12, ADC14, A360, A380, AlSi9Cu3 ac ati. |

| Traethawd Mold | Traethawd Gorwedd >HRC45 |

| Arwydd Cynllun | Sylweddoli oes, Clociad Pudwr, Llithro, Anodio, ac ati |

| Symudiad & Lliw | Gall ei dylunu yn unol â'ch anghenion |

| Proses | Castio llygad o ffioedd uchel |

| Gwerthfawr | Gwerthfawr ISO 9001:2015 |

Gwybodaeth drafod:

| MOQ | 2 set |

| Amser llwch y modd | Sampl T1, am 3-10 wythnos, yn unol â gofyniad y modd |

| Amser arwain cynhyrchu | 2-5 wythnos, yn unol â faint y gorchymyn |

| Telerau taliad mold | 50% T/T arlein gyda PO, balans 50% T/T ar ôl i sampen gael ei gymhwyso |

| Telerau taliad cynnyrch | 30% T/T arlein gyda PO, balans 70% T/T cyn anfon |

| Porth lwytho | Porth Ningbo neu Shanghai |

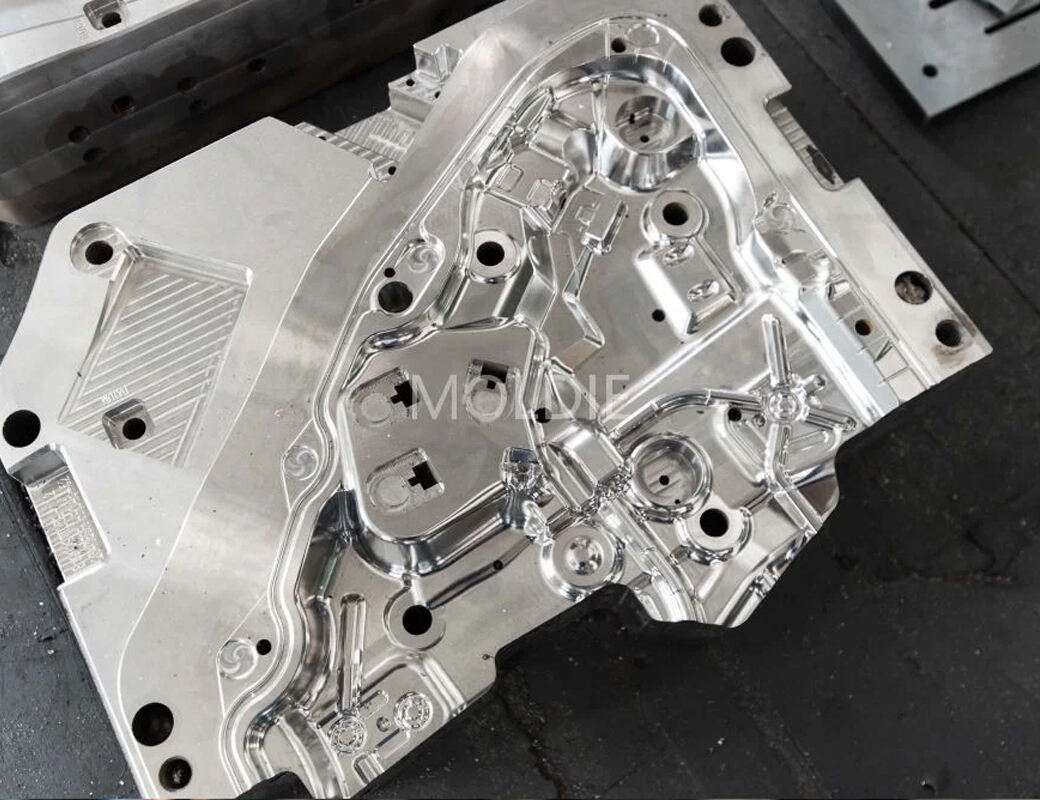

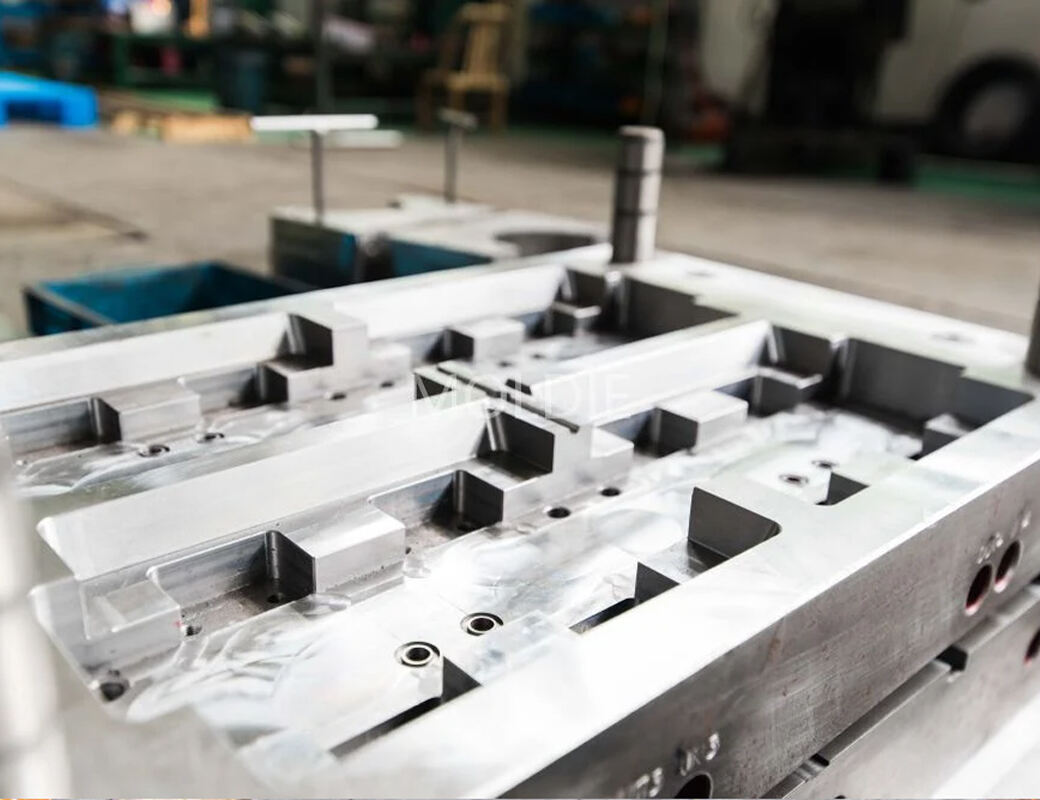

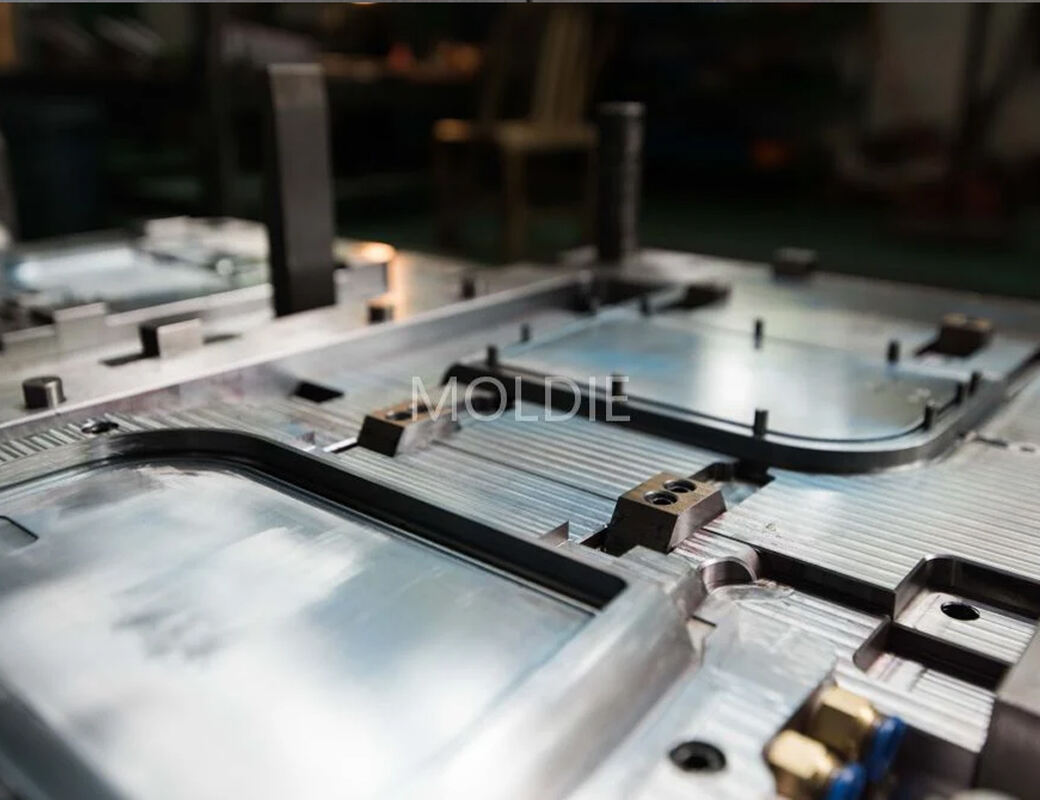

Rai ddelweddau o ein mold lusgo die:

Gwasanaethau Cyfanfodol ar gyfer Lusgo Die

Mae'n cynnwys ein gwasanaethau lusgo die'r proses cyfan o dylunio rhan a chynllunio i wneud y die a lusgo mawr-ego. Rydym yn gweithio'n agos â chi i ddeall eich gofynion unigryw ac i roi datrysiadau cyfeiriol sy'n ateb eich anghenion penodol.

Dylunio Rhan ac Ymgynghori

Mae ein cynghorwyr arbenigol yn defnyddio perfformiad CAD/CAM cyfoethog i gyflawni rhanau te gais sy'n datblygu llawer o fanylion, ariannu a chynhyrchu. Rydym yn creu prototipau gyflym i gadarnhau cynlluniau ac amnewid perfformiad cyn mynd i mewn i gyfrifiadur llawn.

Cynllunio a Chynhyrchu Te

Mae gwaith ddatblygiad Moldie wedi'i gymhwyso gyda'r datblygiad CNC diweddaraf, mesurynnau EDM a chynllunyddiaeth er mwyn cynhyrchu te gais o ansawdd uchel. Mae'n cynnwys ein broses cynllunio te gyda feddalwedd symalig cyfoethog i wella'r systemau gwylwyr, ychwanegu clybiau a threfnu eu hadlewyr, yn sicr bod canlyniadau cael castell dwys a chonsisten.

Castellu a Chynnal Pwst

Gan ddefnyddio masini castellu diweddar a phrocedir rheoli ansawdd cryf rydym yn cynhyrchu raddfa uchel o ranau te gais preswyl gydag hermyg cyfarwydd a chynhwysion dan sylw. Gan gynnwys ein gwasanaethau cynnal pwst, megis trin, cyfreithlon, trethu'r wyneb a chynnal, rydym yn rhoi gwerth i chi â phroduct parod i'w defnyddio.

Pryddesterau Gwasanaethau Llosgi Moldie

Arbenigedd mewn llosgi alwminiwm, syns a maganês

Prototipu gyflym ar gyfer diladur a datblygu dylun

Medrau cynllunio a chynhyrchu llun penodol

Cynhyrchu cyfartalog uchel gan gymhariaeth ansawdd

Gwasanaethau ôl-prosesu llawn

Pris cyfrifol ac amser cyfyngedig gyflym

Gwasanaeth i Fannau Amrywiol

Mae gwasanaethau llosgi moldi Moldie yn cael eu cynnig i wahanol radd o fannau, gan gynnwys cymdeithasol, awyrennol, electronig, cynnill bersonol, a mwy. Mae ein cleientiaid ar draws y byd yn cynnwys breintiau presteg fel Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, BMW, Ferrari, Rolls Royce, Schneider, Phillip, a IEK.

Cymorth â Moldie ar gyfer Eich Anghenion Llosgi Mold

Dewiswch Moldie fel eich partner pwysleisio ar gyfer diesau lusgo o ansawdd uchel a gwybiwch y wahanolrwydd sy'n cael ei wneud gan ein troseddu, ein thechnoleg uwch a'n cymeradwyaeth i achosi. Cysylltwch â ni heddiw i drafod eich brosiect ac gadael i ni eu helpu i roi dy syniadau yn byw.