Discover unmatched precision with our pom plastic injection molding products, featuring ISO and SGS-certified quality, diverse materials, and vivid RAL PANTONE colors.

Constructed using premium mold bases like LKM, HASCO, and DME, our injection molding toys are tailored to perfection.

The mold materials ranging from 45# to 1.2738 promise exceptional endurance. And with a product material palette spanning PC/ABS to POM, they cater to diverse needs.

The magic doesn’t stop there; precision gate types, cold or hot runner options, and injection machine compatibility from 80-1500Ton underline these toys’ adaptability.

Each toy is artistically grained, meeting MT, YS, and HN standards, and elegantly colored per the RAL PANTONE specifications.

Moreover, they are ISO 9001:2015 certificated. Overall, contact us today and invest in them.

MOLDIE specializes in manufacturing and supplying of prototypes and various moulds and dies, such as plastic injection moulds, die casting molds and progressive dies since 2004.

MOLDIE provides various molds & dies to the clients from Germany, USA, Spain, Italy, Russia and so on.

"Good quality" is the base of MOLDIE business, as all MOLDIE staff know quality is essential condition for mechanical products, MOLDIE must keep our clients in a safe condition.

ISO 9001: 2008 certificated.

Advantages:

1. Competitive price

2. Strict quality control system

3. Quick mold making and delivery

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Special info.:

Following customers' requirement to make the molds.

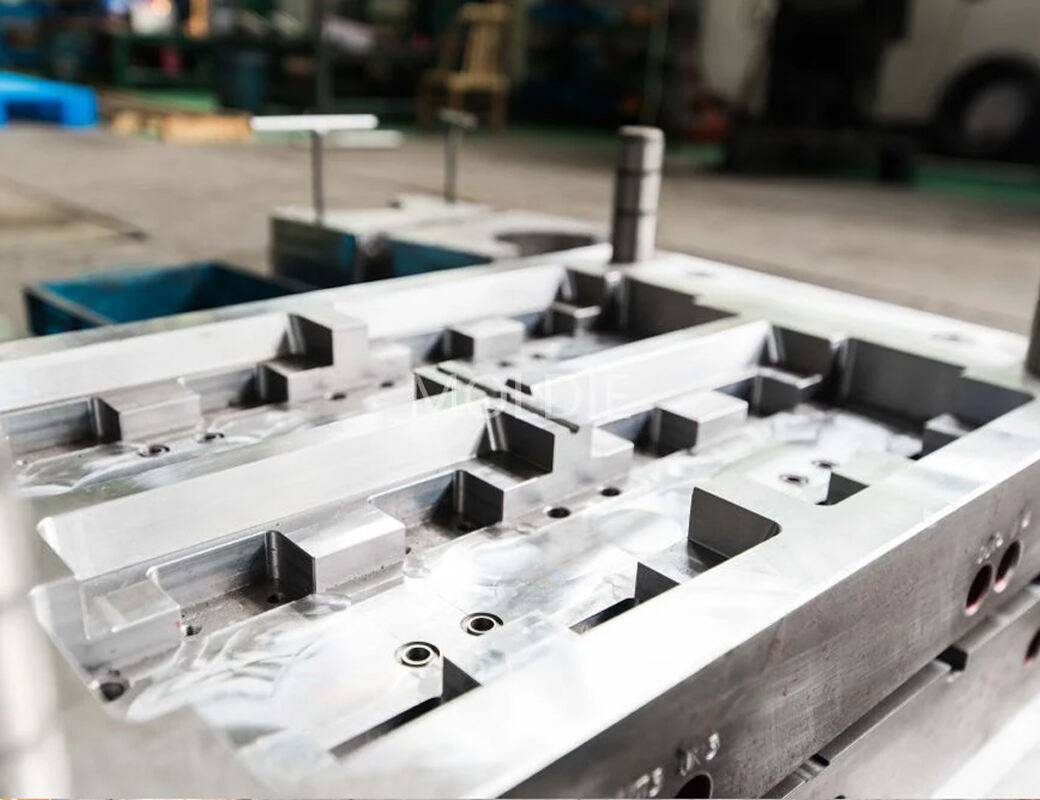

Mold base: LKM C50 standard mould base

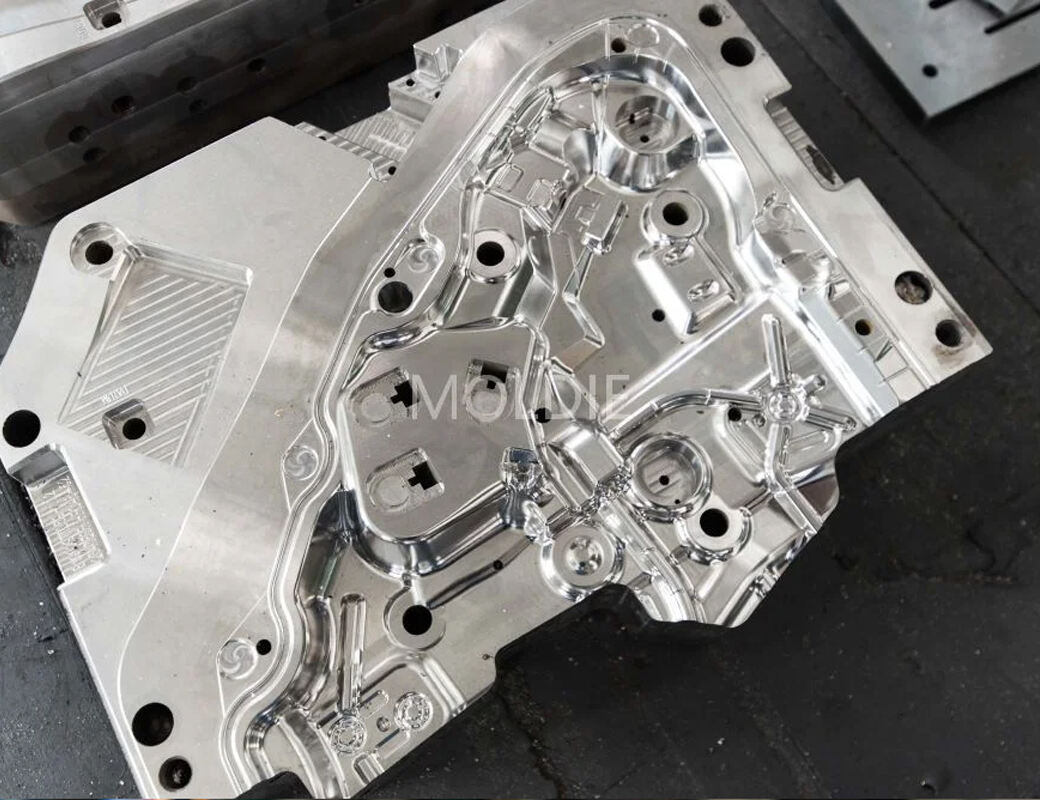

Inserts(cavity and core): H13, 1.2344, 1.2738, 1.2083, 1.2311, NAK80 or the material you required.

Standard parts: HASCO, DME, MISUMI, Punch

Part material: ABS, ABS/PC, PA, PA66+30GF, PBT, PC, POM, PP, PE, PVC and so on

Lead time of first samples: Around 4~7weeks.

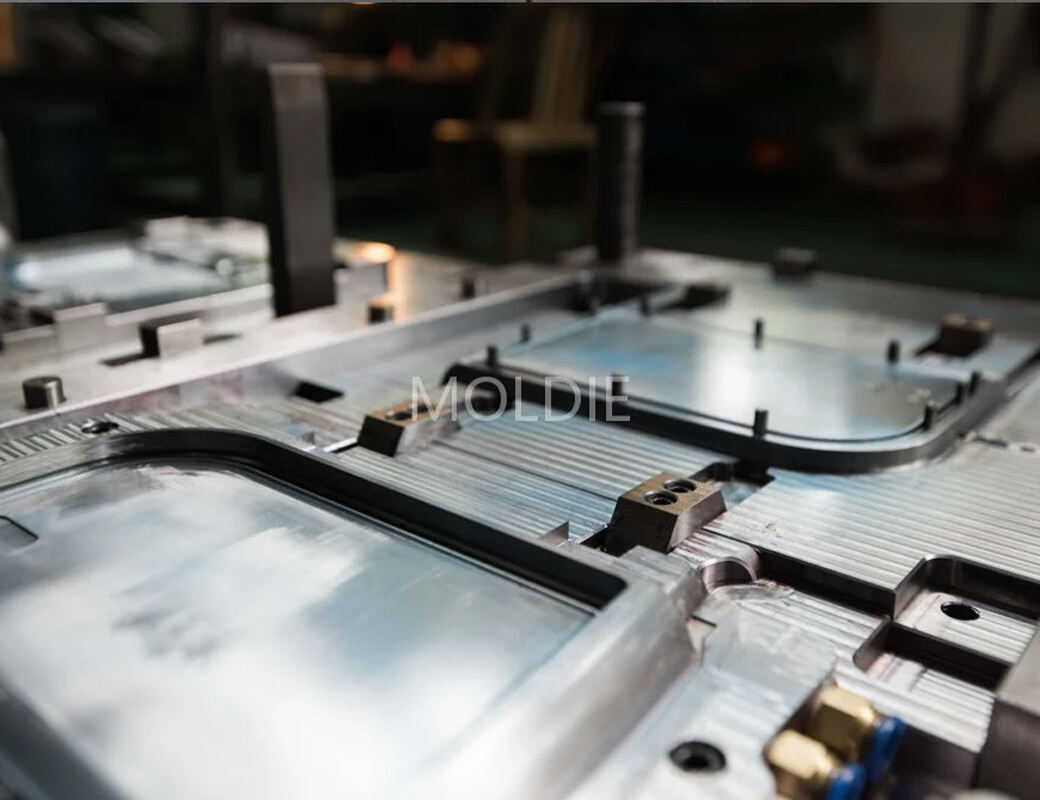

We have one professional engineers team to design the mold and check the design to make sure all are right before production. My engineers follow the molds' production every week to make sure all of them are in schedule; After trial production, we will check the samples about the finishing and dimension to make sure samples are right or not and make report to our clients; We do the final inspection on molds before mold shipment. We are one of professional company to provide you good quality molds with good price in time.

Packaging Details: Carton and pallet, rust-proof protection. Suitable for sea shipment and air shipment and easy to be carried by forklift

| Name | Description |

| Products' info we need to make quotation | Clear Pics/material/size/weight/wall thickness/targetting quantity and etc. |

| Mould Material | 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKd61 etc |

| Mould Base | LKM, HASCO , DME, ect. |

| Cavity | Single/multi |

| Runner | Hot/cold |

| Mould Design | 3D/2D Drawing |

| Design Days | 3 days |

| Design Software | UG, PROE, CAD, CAE, CAM, CAXA ect |

| Plastic Material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect |

| Mould Life | 300, 000-1, 000, 000 shots |

| Injection System | Pin-point-gate |

| Polish System | Mirror Polish |

| Payment | 50% of Deposit by T/T, 50% of Balance by T/T |

| Delivery Time | 30-45days |

| Specification | Depends on customers requirements |