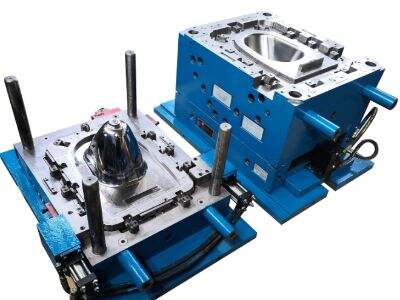

इन्जेक्शन माउल्डिंग, मोल्डी कंप्यूटर माउल्ड से, विभिन्न प्रकार के उत्पादों को बनाने के लिए एक अद्भुत तकनीक है। यह प्रक्रिया आपको शीर्ष डिज़ाइन बनाने की अनुमति देती है जो दिखने और काम करने में अद्भुत होती है। हम यहां कुछ विभिन्न कारणों पर चर्चा करेंगे कि कस्टम प्लास्टिक इंजेक्शन मोल्डिंग आपके उत्पादों के उत्पादन के लिए सबसे अच्छा विकल्प है।

किस डिज़ाइनर चुनाव की शुरुआत कस्टम इन्जेक्शन माउल्डिंग के लिए गुणवत्तापूर्ण डिज़ाइन के लिए

कस्टम इन्जेक्शन माउलिंग कई फायदों से संबंधित है, जिनमें से एक यह है कि बेहतरीन सटीकता के साथ जटिल और विस्तृत डिज़ाइन बनाने की क्षमता। यह आपके उत्पादों को पेश-professional और उस चमकदार खत्म देने की अनुमति देता है। ऐसे में, आपके द्वारा बनाए गए प्रत्येक उत्पाद एक ही उच्च गुणवत्ता वाला उत्पाद होगा और आपके पास हो सकने वाली हर आवश्यकता को पूरा करेगा। Moldie पर, हमारे पास आपकी Creative Vision को वास्तविता में परिवर्तित करने के लिए विशेषज्ञता वाली टीम है, Concept से लेकर Accurately और Meticulously Created तक।

कस्टम इन्जेक्शन माउलिंग को चुनने से क्यों समय और पैसा बचता है

जब आप उत्पाद विकास में होते हैं, तो यह सदैव समय-और-लागत पर निर्भर होता है। जब यह ठीक से किया जाता है, तो Custom इंजेक्शन मोल्डिंग एक बुद्धिमान विकल्प है जो दीर्घ काल में आपके लिए पैसा बचाने में मदद कर सकता है। अपने उत्पादों के अनुसार विशेषज्ञ मोल्ड बनाने से आपको सामग्रियों का उपयोग अधिक कुशलतापूर्वक करने में मदद मिलती है और अपशिष्ट कम करने में मदद करता है। इसका मतलब है कि आप सामग्रियों पर इतना अधिक खर्च नहीं करेंगे। Moldies अपनी सरल, प्रभावी प्रक्रिया के साथ आपका मौल्यकालिक समय भी बचाते हैं और आपके उत्पादों को ग्राहकों के हाथों में तेजी से पहुँचाते हैं।

फ्लेक्सिबल इन्जेक्शन माउंडिंग फॉर कस्टम डिजाइन सॉल्यूशंस

डिजाइन फ्लेक्सिबिलिटी कस्टम इन्जेक्शन माउंडिंग का एक और प्रमुख लाभ है। हम आपकी सटीक आवश्यकताओं को पूरा करने के लिए तैयार हैं, चाहे आपको कुछ ही उत्पादों की आवश्यकता हो या एक बड़े पार्टी की। जो कस्टम इन्जेक्शन माउंडिंग को बहुत अधिक फ्लेक्सिबल बनाता है। चाहे आपका मॉडल एक सदैव लोकप्रिय हिट हो या एक सीमित संस्करण का विलासिता-भरा शो हो, Moldie's डिजाइन टीम आपके साथ साझेदारी कर सकती है और अपने कला कार्यों के अनुसार अद्वितीय मोल्ड बनाने में मदद कर सकती है। कस्टम इंजेक्शन मोल्डिंग वास्तव में आपके डिज़ाइन के पहलुओं को आकार दे सकती है, और आपको आगे खोजने के लिए स्पष्ट मार्ग दे सकती है, विशेष रूप से यदि आपको बहुत सारे उत्पाद तैयार करने होंगे।

अपने उत्पादों को संगत और कुशल बनाएं

उत्पाद बनाना अक्सर संगति और कुशलता की बात होती है। कस्टम इन्जेक्शन माउल्डिंग आपको संगति बनाए रखने की अनुमति देती है और यह सुनिश्चित करती है कि हर उत्पाद समान गुणवत्ता के साथ माउल्ड किया जाता है। यह भी महत्वपूर्ण है कि आप जिस प्रौद्योगिकी का उपयोग करते हैं, उसे आप नए उत्पादों के बैच बनाने के लिए लागू करें ताकि संगत परिणाम प्राप्त हों। संभावना है कि वे निश्चित रूप से संगत होंगे और यह आपको अपने ब्रांड के लिए मजबूत प्रतिष्ठा बनाने में मदद करेगा, जो ग्राहकों को संतुष्ट रखता है और अधिक खरीदारी के लिए वापस आते हैं।

कस्टम इन्जेक्शन माउल्डिंग: अपने उत्पादों को बाजार में कुशलतापूर्वक लाएं

आज के समय में बाजार में तेजी से पहुँचना सफलता के लिए महत्वपूर्ण है। यह इसका मतलब है कि कस्टम इंजेक्शन माउल्डिंग के साथ आप अपने उत्पादों को ग्राहकों तक पहुँचा सकते हैं, जितना आपकी कल्पना नहीं होती। मोल्डी की नवाचारपूर्ण प्रक्रियाओं और उन्नत मशीनों के साथ, आप आसानी से अपने डेडलाइन को पूरा कर सकते हैं और प्रतिस्पर्धा से एक कदम आगे रह सकते हैं। कस्टम इंजेक्शन माउल्डिंग का चयन करना आपको अपने पूरे उत्पादन प्रक्रिया को सरल बनाने में सहायता करता है, और आप इसे तेजी से और अधिक प्रभावी ढंग से कर सकते हैं। इसका मतलब है कि आप अपने अद्भुत उत्पादों को ग्राहकों के हाथों में तेजी से पहुँचा सकते हैं।

Table of Contents

- किस डिज़ाइनर चुनाव की शुरुआत कस्टम इन्जेक्शन माउल्डिंग के लिए गुणवत्तापूर्ण डिज़ाइन के लिए

- कस्टम इन्जेक्शन माउलिंग को चुनने से क्यों समय और पैसा बचता है

- फ्लेक्सिबल इन्जेक्शन माउंडिंग फॉर कस्टम डिजाइन सॉल्यूशंस

- अपने उत्पादों को संगत और कुशल बनाएं

- कस्टम इन्जेक्शन माउल्डिंग: अपने उत्पादों को बाजार में कुशलतापूर्वक लाएं

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

HU

HU

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

IS

IS

HY

HY

AZ

AZ

KA

KA

BS

BS

LA

LA

KY

KY