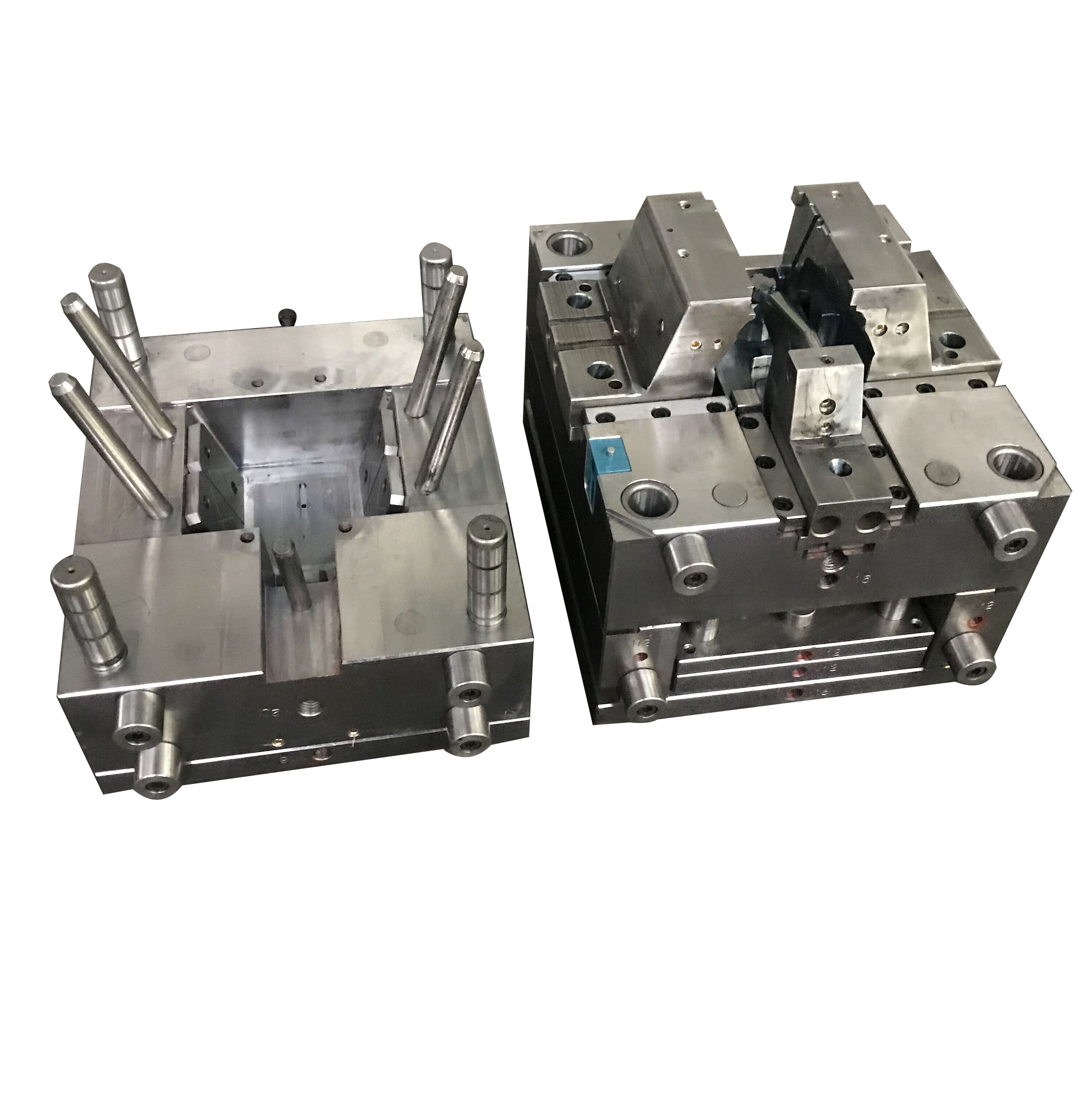

Γεια σας παιδιά! Σήμερα θα σας δείξουμε πώς να διατηρείτε μούλος εισαγωγικής μολύνσης με τον σωστό τρόπο ώστε να μπορούν να λειτουργούν για δεκάδες χρόνια. Τα μολδάβια καταχύσεως είναι κρίσιμα συστατικά στην παραγωγή πολλών αντικειμένων, έτσι πρέπει να γίνεται η κατάλληλη φροντίδα για να εξασφαλιστεί ότι λειτουργούν αποτελεσματικά κατά τη διάρκεια της ζωής τους. Η Moldie, μια φίλος μας, έχει μερικά καλά συμβουλία για το πώς να φροντίζετε αυτά τα μολδάβια ώστε να κάνουν το έργο τους.

Πώς να χρησιμοποιήσετε επιχειρησιακό υγρό για καλύτερη απόδοση;

Χρήση Εμβαδωτικού: Αυτό είναι πολύ σημαντικό να γνωρίζετε για την διατήρηση των μούλων υποχώματος. Το εμβαδωτικό είναι σαν ηλιοπροστασία για το δέρμα σας. Το εμβαδωτικό είναι σαν ηλιοπροστασία: προστατεύει τα μούλα από τον ήλιο. Προλαμβάνει τα μούλα από τη χρήση και από το να γίνονται ριζωμένα ή διαβεβαίωτα. Σύμφωνα με το Moldie, η χρήση ενός εμβαδωτικού ποιοτικού επιπέδου θα βοηθήσει να επεκταθεί η ζωή του μούλου. Εφαρμόστε το εμβαδωτικό και βεβαιωθείτε ότι είναι εξισορροπημένα διακινημένο στην επιφάνεια του μούλου. Αλλά φεύγετε από υπερβολικό εμβαδωτικό εδώ, γιατί αυτό μπορεί να προκαλέσει προβλήματα αργότερα, όταν εργάζεστε με τα αντικείμενα με τα μούλα.

Τα Μούλα Ελέγχονται Για Να Μείνουν Δυνατά

Ένα άλλο καλό συμβουλείο είναι να ελέγχετε τα μορφοποιητικά περιοδικά για να βεβαιωθείτε ότι είναι σε καλή κατάσταση. Τα μορφοποιητικά ελέγχονται περιοδικά ώστε να αναγνωρίσουμε οποιαδήποτε προβλήματα, συμπεριλαμβανομένης της έξωσης ή καταστροφής. Εάν ένα μορφοποιητικό είναι κατεστραμμένο, μπορεί να οδηγήσει σε λάθη στην κατασκευή των αντικειμένων και οι επισκευές μπορούν να είναι πολύ δαπανηρές. Γι' αυτό είναι σημαντικό να ανιχνεύσουμε οποιαδήποτε προβλήματα μορφοποιητικών νωρίτερα. Κάντε οπτική εξέταση μετρώντας προσεκτικά τα μορφοποιητικά για οποιαδήποτε προβλήματα, το Moldie βοηθά. Ειδικά εργαλεία όπως χειρονεύματα ή ολισθηματικά συσκευάσματα μπορούν επίσης να χρησιμοποιηθούν για να ανιχνεύσουν προβλήματα, κρυμμένα μέσα στα μορφοποιητικά και μη φανερά στο γυμνό μάτι.

Επισκευή των περισσότερων προβλημάτων με τα μορφοποιητικά

Διατήρηση καταπλαστές πλαστικού δεν είναι πάντα εύκολη δουλειά, αλλά αυτός ο διαδρομέας θα αντιμετωπίσει μερικά κοινά προβλήματα που μπορεί να αντιμετωπίσετε και το πώς να τα λύσετε. Κοινό πρόβλημα είναι ότι οι καταχώρησεις είναι κολλημένες μαζί. Αυτή η κολλώση μπορεί να οδηγήσει σε σοβαρές ζημιές στις καταχώρησεις. Η Moldie συστήνει τη χρήση ενός συγκεκριμένου απελευθερωτικού φαρμακού για να αποφευχθεί αυτό το ζήτημα. Αυτό το φάρμακο δρα κάπως όπως ένα μπάριερ που βοηθάει στην αφαίρεση της καταχώρησης από τον υποδοχέα με την επιτροπή μιας καθαρής αποχώρησης από το σώμα του υλικού (το αντικείμενο που φτιάχνεται). Διάβρωση: Άλλο κοινό πρόβλημα είναι η διάβρωση (που συμβαίνει όταν οι καταχώρησεις εκτίθενται σε διαβρωτικά ή βλαβερά υλικά). Η Moldie πρότεινε να λειτουργεί σε ένα περιβάλλον με λιγότερη οξείδωση, χρησιμοποιώντας χαμηλότερες σύμμιξεις διάβρωσης ή υλικά που δεν οξειδώνονται, ή να καθορίζουν επιφανειακές μεταχειρίσεις ή καλύψεις στον αισθητήρα για να προληφθεί η διάβρωση για μακροχρόνια λειτουργία.

Συμβουλές για την δημιουργία ενός καλού σχεδίου συντήρησης για καταχώρησεις

Έτσι, η Moldie προτείνει ένα καλό σχέδιο συντήρησης για να διατηρείτε τα μούλδινγκ επιβολής υψομάλλων σας. Θα πρέπει να λεπτοποιεί τα συγκεκριμένα βήματα που πρέπει να ακολουθηθούν για να εξασφαλιστεί ότι τα μούλδινγκ σας παραμένουν καθαρά, λιαρωμένα και ελεγχόμενα κατά την προγραμματισμένη χρονική περίοδο. Χρειάζεστε επίσης έναν χρονοδιάγραμμα ώστε να ξέρετε πότε να κάνετε τι. Να έχετε ένα σχέδιο δράσης εξασφαλίζει ότι δεν παραλείπετε κανένα βήμα στην διαδικασία και ότι τα μούλδινγκ σας συνεχίζουν να λειτουργούν για χρόνια. Ένα καλό σχέδιο συντήρησης θα σας υπενθυμίζει να κάνετε όλη τη συντήρηση που απαιτείται για να τα διατηρήσετε στο καλύτερο επίπεδο που μπορείτε.

Τα μούλδινγκ επιβολής υψομάλλων φτάνουν στην πρώτη γραμμή κάθε προϊόντος που παράγουμε, και επομένως να τα διατηρούμε καλά είναι κρίσιμο για την επεκτένση της ζωής τους. Η Moldie μας συμβουλεύει να χρησιμοποιούμε ποιοτικά λιαρώματα, να ελέγχουμε τα μούλδινγκ προφαντικά για σχίσματα ή άλλες μορφές ζημιάς, να επιλύουμε κοινά προβλήματα και να ιδρύσουμε έναν ισχυρό προγραμματισμό συντήρησης. Ακολουθώντας αυτά τα βήματα, θα έχετε τα μούλδινγκ σας να λειτουργούν το καλύτερο δυνατό, με περιορισμένο διάλειμμα και χωρίς χρόνο να χάνετε σε επισκευές. Μακροχρόνια. σχεδιασμός μούλου και η διατήρησή τους. Παρόμοια με τον τρόπο που χρειάζεται να διατρέφουμε το σώμα μας για να είμαστε υγιείς, τα μούλδες καταχύτησης χρειάζονται διατήρηση για να είναι χρήσιμα για μακρά χρονιά!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

HU

HU

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

IS

IS

HY

HY

AZ

AZ

KA

KA

BS

BS

LA

LA

KY

KY