Aluminium casting tools are the first thing to gather, similar to the Moldie's product like pvc moulding manufacturers. As for the Aluminium, you will be needing a furnace or melting pot to heat it to the point that it melts. You will also need to have a mold that the melted metal can be poured into to create the right shape. This is an incredible discovery, but safety is the most important part of the process. You want to wear some PPE like gloves to protect your hands, goggles to protect your eyes, and an apron to protect your clothes. You have to wear this protective gear so that you do not get burned or hurt while hot metal.

The molten Aluminum is then poured into the mould. Do this carefully, ensure that Depending on the shape you want to make, this might require a specific type of mold or the addition of extra openings to allow for air or steam to escape. This is so you can avoid complications towards the end of the process. After you have poured the melted aluminium into the mold, it takes time to cool and harden. A cooling process after this step is critical for the aluminium to be coaxed into the shape of the mold.

To extract your casting, gently open the mold once the aluminium has cooled and set inside the mold, along with the plastic injection molds for sale by Moldie. While doing so, Please be careful as you could snap or break a part of the object. At this point, the metal can still be somewhat soft, so you need to watch out for anything delicate breaking.

Experiment with molds: Do not hesitate to experiment with different types of molds and materials, as well as the Moldie's injection molding company for sale. You can also create custom shapes using sand, plaster, or even 3D-printed molds. Ensure that whatever mold you use is rigid enough to support the melted aluminium's weight, and space enough for it as it expands or contracts while cooling.

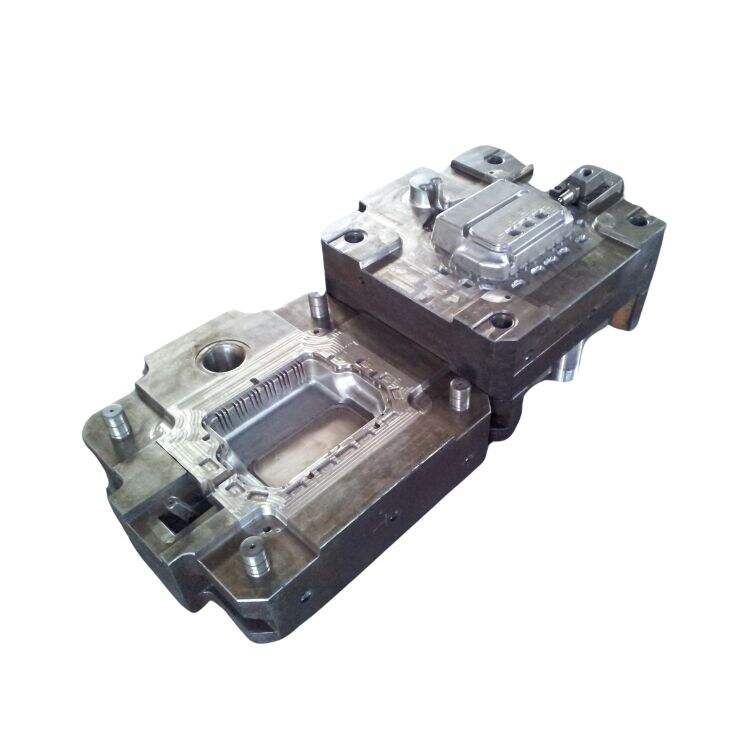

Complex Shapes: The casting can create very complex shapes, and the biggest benefit of a casting is that you can get them very easier, identical to custom molded plastics produced by Moldie. Modern technology allows designers to easily create highly detailed designs, facilitated by advanced molds and the use of various software to depict what the desired design will look like, something difficult to replicate using other methods.

Simulated under attack using ideas from other metalworkers and blacksmiths from the past and present Studying their methods and styles will motivate you and also facilitate your growth, similar to the Moldie's product like in jection moulding. There are also workshops and online communities which you can join to discuss your experiences, and receive feedback from others.

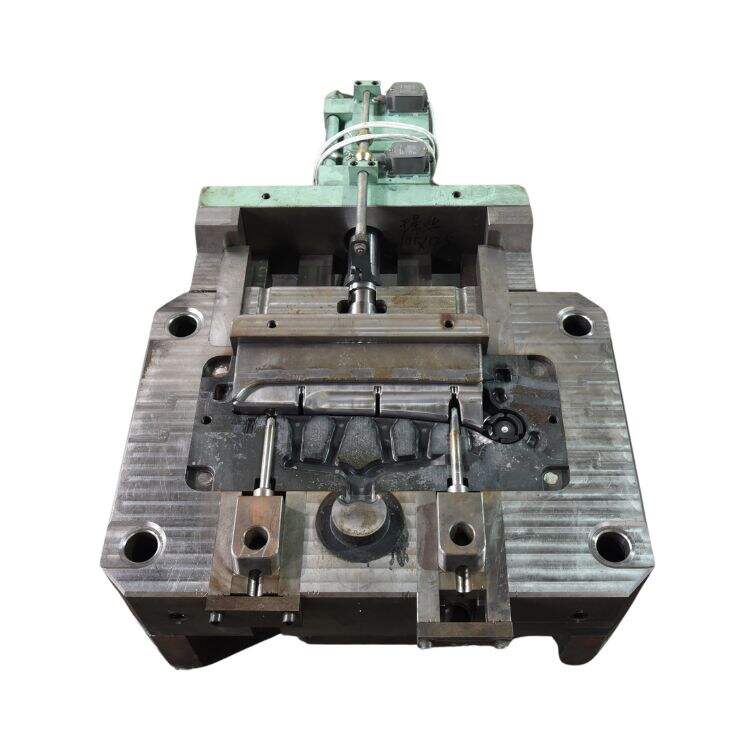

Our molds are known for their exceptional quality and precision. Testing equipment is an indispensable means of guaranteeing the mold manufacturing process. A high-quality quality management team with precise testing equipment is the guarantee for creating high-quality molds. The quality inspection department is equipped with two high-precision three-coordinate and 3D scanners. Moldie promises to issue a full-size report within three days after the product trial, and a 3D scan report within two days. Moldie has been a supplier with ISO certificate.

The engineers at Moldie have extensive design experience and comprehensive development knowledge. Moldie will scan any provided samples and generate a product blueprint. Once the customer reviews and approves the blueprint, we can begin mold assembly and drawing design based on the customer’s existing project.Moldie Engineering Center consists of more than 30 engineering and technical personnel. They can deal with engineering, design simulation, machining, inspection to support and guarantee the quality and function the tooling we constructed.

Our comprehensive logistics solutions provide end-to-end services, from order processing to final delivery. We leverage advanced tracking systems and a global network of carriers to ensure timely and secure delivery. Since its establishment, Moldie. has provided professional solutions for more than 50 clients and 20 countries around the world. Moldie has cooperated with DHL, Fedex and UPS for fast sample delivery. Moldie can ship goods by sea, air and train in good packing way suits for global transportation.

Moldie has provided injection & plastic parts solutions since 2008. 3000+ square meter facility enhances us to serve clients worldwide. From the automotive sector, where we serve prestigious brands like Mercedes-Benz, Volkswagen, Audi, Maserati, Chrysler, and GM, to leaders in other fields such as Schneider, Phillip, and IEK. With a reputation for excellence in OEM/ODM services, Moldie is not just a manufacturer; we are innovation partners, providing comprehensive services including part design, prototype creation, mold design, and large-scale mold production.